Québec City, March 21, 2019 – Without offering any direct measures to support mineral development in Québec, the first budget tabled by the Legault government includes some promising measures to accelerate the issue of environmental authorizations, support infrastructure development and promote the energy transition. In the view of the Québec Mining Association (QMA), the budget shows that the Québec government wants to stimulate the economy and that major industrial projects that contribute to this objective are welcome.

« The government’s 2019-2020 budget does not contain any direct tax measures to give mining companies more breathing space. However, it does provide support for a number of initiatives which, indirectly, promote mineral development in Québec. In its budget, the government sends a clear message in favour of a stronger economy, and the mining industry will be ready and willing to support the government’s objectives. »

« Overall, the QMA reacts positively to the Legault government’s first budget. It clearly expresses the goal of accelerating approval for the environmental aspects of investment projects, and therefore addresses a concern frequently raised by our members and by the QMA. We hope that this measure will quickly lead to results. »

« Mining companies spend around $8.5 billion every year on their operations. They are key players in economic development for Québec as a whole, and not just in the mining regions. Since they contribute $1 billion each year in taxes to the Québec government, it is clear that the government has an interest in supporting the mining sector to ensure Québec’s socio-economic prosperity. »

– Josée Méthot, QMA president and CEO

Relevant measures in the budget

The budget measures welcomed by the QMA include:

• Reducing approval times for investment projects, by hiring additional personnel;

• Allowing the costs associated with obtaining and maintaining sustainable development certification to be deducted as an allowance under the mining tax regime;

• Providing support for training for the local and Aboriginal workforce in the North, in particular by

o developing training in response to certain special needs in the North; and

o hiring liaison officers for optimizing the integration of Aboriginal workers into the labour market.

• Encouraging businesses to use artificial intelligence;

• Improving regional infrastructures:

o ensure access to a high-speed Internet connection and broadband cellular network in all regions;

o support the extension of the natural gas distribution network;

o support the implementation of transportation logistics for liquefied natural gas on the Côte-Nord;

o support the development of the Société ferroviaire et portuaire de Pointe-Noire;

o support the QcRail project;

o support the development of multi-user infrastructure in northern areas.

• Supporting businesses in their energy transition process, in particular by

o introducing a component for large projects under the Technoclimat program;

o introducing a component for large industrial projects under the ÉcoPerformance program.

About the Québec Mining Association

The Québec Mining Association (QMA) was founded in 1936 and speaks proactively for mining companies involved in exploration, extraction and processing, mining contractors and junior mining companies, along with suppliers, institutions, non-profit organizations and other mining sector partners. It is proud of the 40,540 jobs and total expenditure of $8.5 billion generated by Québec’s mining industry over the last year. The QMA’s mission is to promote, support and proactively develop a responsible, committed and innovative mining industry in Québec.

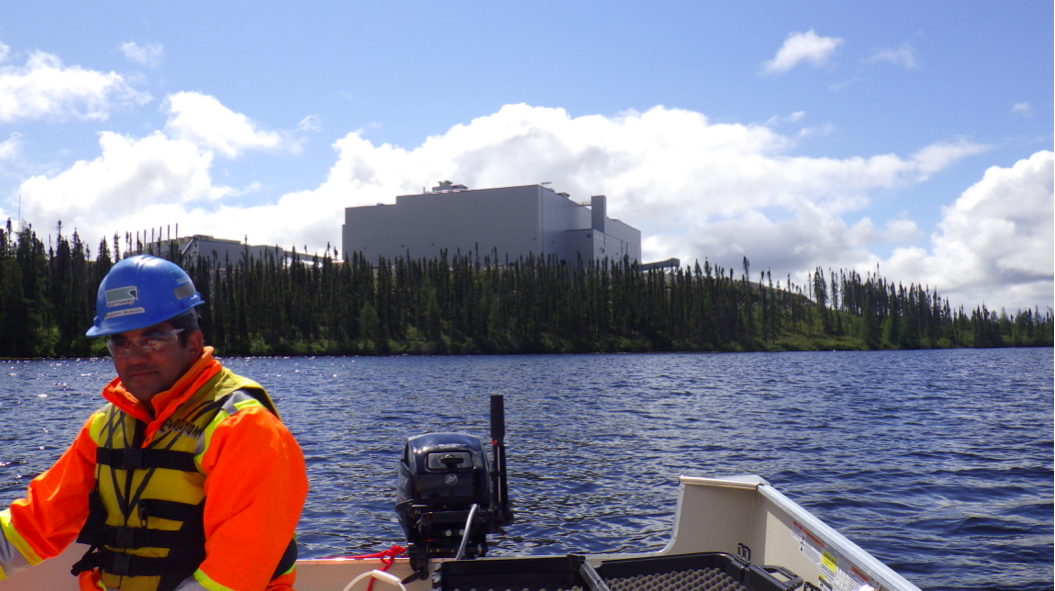

The picture shows environment technician Charles Dubois on Lac Lagopède and, in the background, the ore treatment plant.

The picture shows environment technician Charles Dubois on Lac Lagopède and, in the background, the ore treatment plant.